Hi kids! Tonight I bodgered my track light kit! (It's one of those British words - and yes, it is legal!) The plan is to liberate them from the track, so each unit has its own power and can be placed wherever I want. Above you see what they look like opened up - inside is the transformer itself plus two red wires and a green wire. I happen to know the green wire is the ground, but had to trace the path of electricity to work out which red wire goes to positive and which to negative. You can see in the picture above where I marked them - one with a black sharpie and one with white tape. Then I cut off the wires. Man, that green wire is short!!! I knew that one would give me trouble later on....

Now I've drilled a hole through the side of the plastic casing for the cord to pass through. I picked up some 13 amp grounded utility cords with pre-stripped wires coming out the end, along with a pack of those little orange twist-connector things. It's a tight fit, but the three connectors can be jammed down into the existing space inside the casing. And yes, those little green wires gave me hell!!! But I managed.

After getting everything connected I gobbed hotglue all around the hole I drilled - inside and out, basically to form a solid fillet around the end of the cord to keep it secured in place. If it manages to slide out I don't have any faith in those little connectors holding all the weight of the cord! Finally I replaced the lid, sealing it all together again into its attractive contemporary housing.

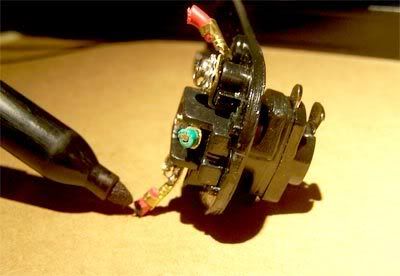

I did it this way because I plan to cut short sections of the track and gaffer tape them wherever I want one of the light fixtures - then I can just twist the fixture into place with a satisfying click! Not sure this is the best plan - I thought about cutting the little cord that runs between the transformer and the lighting unit itself so I could separate the fixture from the transformer housing, but if I did that the connections wouldn't be tucked away inside a nifty casing - they'd be right out in the open for all to see. Hmmm.... unless I got myself a soldering iron and tried to do it right at the connection to the printed circuit board itself.... something to consider for the future maybe.

Anyway, it worked like a charm!!! These lights are bright and white as can be! Quite satisfying after the rather dim orangey Par-16 birdies I bought from Musician's Friend recently. Oh sorry - I meant to mention those before now. The price is definitely right - $30 for a pair of these cool-looking little lights (and though the website mistakenly reports that they don't come with filter holders, I can tell you happily that they actually DO). These run on full mains power - 120 volts as opposed to the 12 volt track lights. The Par 16 birdies are a bit dim - they're 50 watt fixtures. Premiere Lighting (which I've recently added to my links on the right) carries 75 watt par 16's that I'd like to try out.

And yeah, I know I'm accumulating quite a stash of lights. That's the point - I want to have enough on hand at any time to supply whatever crazy lighting situation I dream up. I'm thinking about getting 3 more of the track light units at some point - they seem like excellent little powerhouses that can be fully tailored with the accessories found at the Solux site.

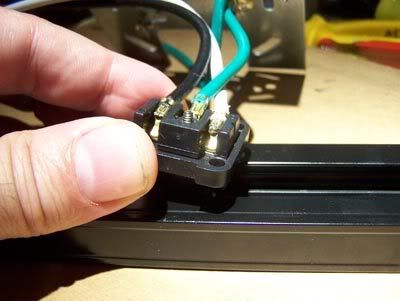

I decided to add a bit here to explain how I traced the electric lines. This little widget is the twist lock connector that pops in one end of the track and gets connected to the mains power. It fits into the track the same way the light units do - push it in....

And twist 90 degrees.

Here you can clearly see there are three metal tabs on top. One on the left and two on the right. These tabs make contact inside the track with copper strips that run the full length of the track. If you look closely, you can see the black wire goes to the side with only one tab, while the white wire goes to the side with two tabs.

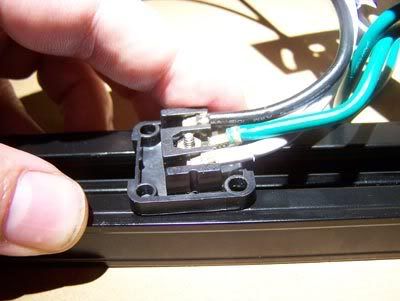

Here's the "lid" from one of the tracklight units. As you can see, it has the same three metal tabs to fit into the track. I wish I had gotten a pic of marking the wires before i cut them all off, but this will have to do. I'm making a black mark here on the (red) wire that goes into the side with one tab.

See.... takes a lot of explaining, but really pretty simple. I really don't know which is positive and which is negative (not sure those terms even really apply - I've heard one is actually called the hotwire and the other is called the neutral wire). But it's not important to know that - you only need to know which wire to connect where, and now we have that vital info. Once you've marked the black wire, there's no need to mark the other one - just think of it as the *unmarked* wire, and it represents the white one. the wire you just marked with the black marker attaches to the black wire in the power cord - the unmarked one attaches to the white wire, and (simple enough) the green wire attaches to the green wire. - Am I overexplaining now?

2 comments:

"Tonight I bodgered my track light kit"

We'd more likely say

"Tonight I bodged my track light kit"

The characteristics of Bodging is that it uses components in a way that they were never designed to be used. A bodge must work (otherwise it would be a hash as in "he's made a right hash of that"), a bodge can be either temporary or permanant, a bodge does not need to look good as functionality is it's main purpose.

So in summary, your lamp modification is a top bodge.

Ah, thank you! Or should I say Cheers!!

I've just been culturally enriched. I guess it was a bodge then, since I didn't botch it (like I did the term).....

Post a Comment