This, my friends, is what I call the Lightcannon.

It's a further refinement/ modification to the Solux Framing Art Light. I detailed my first round of mods to it in these posts. It worked, but with some issues - namely, due to its rather rickety construction and pressure-fit components, it had a tendency to sag and droop like a Dr. Seuss Spyglass, making it very hard to get precise accuracy, plus once you did get it aimed where you wanted, it could slowly droop... impercieptibe except when played back in your animation, when it becomes VERY noticeable. In fact, I have an example posted. Check out the background lighting in One Good Yank. This is unacceptable... in stopmotion everything must stay exactly where you put it until you move it yourself.

I partially solved the problems with this makeshift brace made from a turkey skewer:

It did snug up the assembly nicely, countering all that cartoonish sagging, but it's bulky and dangerous -- those chromed points sticking out right at eye level. Also, the yoke attaching it to my lighting grid was weak and couldn't be secured very well. I tried using a piece of folded-up paper jammed behind it, which helped somewhat but not enough.

So today I set about to improve it.

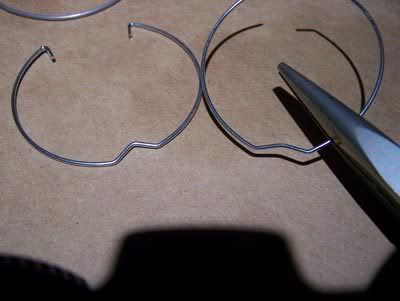

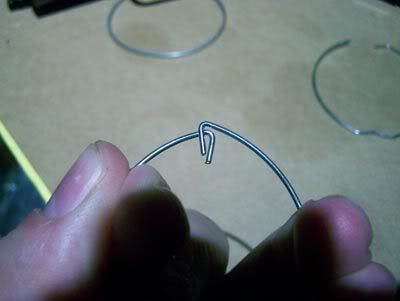

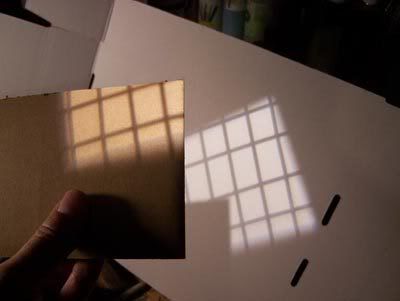

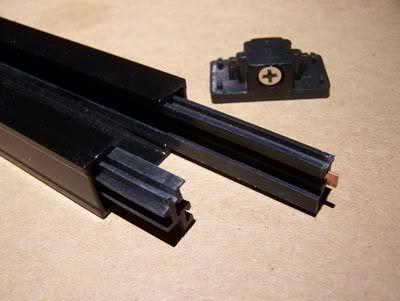

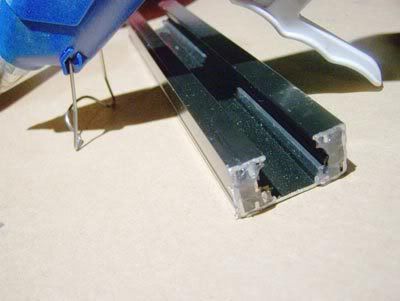

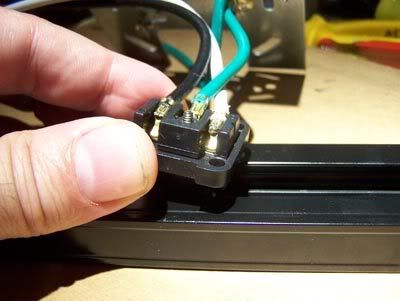

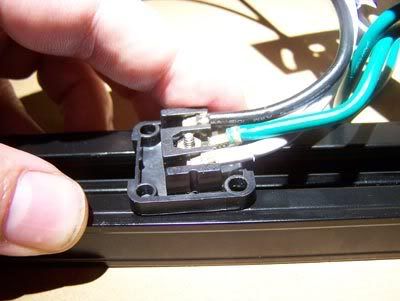

... based on the discovery that the snout/ yoke assembly from a cheap PAR16 (known as a Birdie) pressure-fits perfectly onto an ordinary track lighting unit. As so:

Here's one of my Blackbirds, with the Framing Optic Assembly of a Solux Framing Art Light laying next to it:

I tried fitting the Adapter Ring into the snout:

Success!! It fits, nice and tight!!

So I fitted the rest of the Solux assembly in place...

So far, so good... but when I plugged it in to test it, a problem:

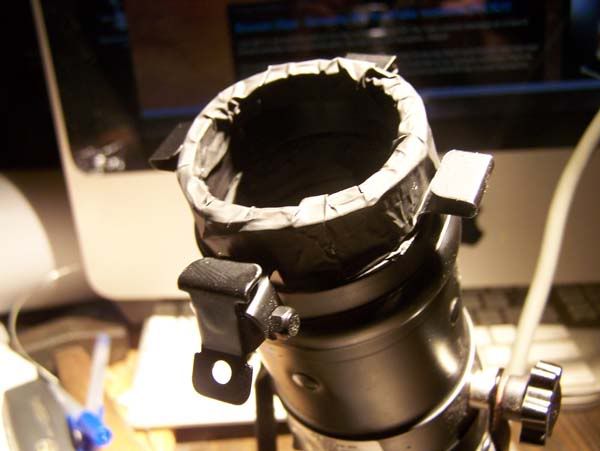

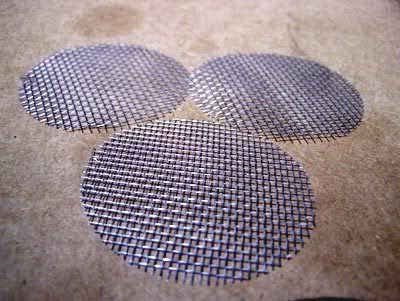

A LOT of light leaks out as you can see. All this spill light sprays out onto the set where you don't want it. Wish I would have got a picture of that. But then, this tut is already ridiculously long and filled with too many pictures. Anyway, my first attempted solution was to jam some Blackwrap in there:

It's designed for use with lights to block out unwanted spill. But it was impossible to arrange it right in there, too many compound curves to deal with. I could have just wrapped it around the outside of the fixure, but I wanted a clean permanent solution, not an ugly blob of black foil hanging from my grid!

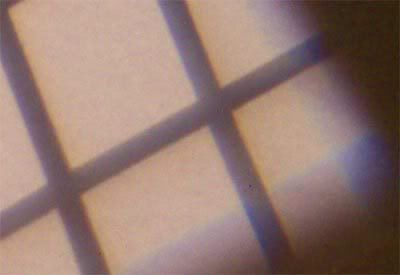

It didn't get rid of all the spill:

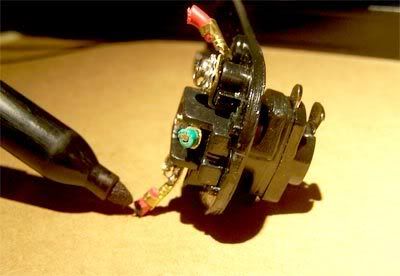

So I decided to try some Epoxy Putty:

... And Voila!! No more spill!! And not only is it fully functional now, but it looks a heck of a lot like a high-tech Ellipsoidal fixture...

... Which is exactly what it is really.

I've also ordered another 3-unit Tracklight kit from Lamps Plus, a couple pairs of the cheap PAR 16's from Musician's Friend, and another Solux Framing Optic Assembly. I'm glad I detailed out exactly how I did all that modding, because I'll need to go back and check my notes for specifics. But when I'm done, I'll have two more Blackbirdies (for a total of 4) and another Lightcannon (to make a pair) to add to my lighting grid... that should be enough for just about any lighting situation.

*** EDIT***

I came up with a better name than Lightcannon. I'm calling it the Ellipsis. An ellipsis is those three little dots that represent missing text...

Yeah. THOSE three little dots. Essentially it's an edit used to shorten something. It's also used in filmmaking, with the same meaning. It's an edit used to cut out unnecessary action or time... example you see someone go to bed, then cut to them waking up in the morning. It edits out the 8 hours of them sleeping. So, an Ellipsis is an abbreviation. In this case, MY ellipsis is an abbreviation of an Ellipsoidal spotlight!

Heh... I tried a lot of names for it... Mini Ellipsoidal, Micro-Ellipsoidal etc... too much of a mouthful!! But now that I've ABBREVIATED it, it works! so...

ellipsis it is!!